Main features

The bitumen-polymer emulsion can be used for virtually any insulation work.

A completely unique new generation water-insulated surface can be created with properties never seen before. With hoses up to 60 m long that can be applied to any geometric shape and configuration surface, the kit allows work in remote architectural areas and hard-to-reach places.

Odorless;

Strong adhesion to any building material, surface;

Self-healing for minor injuries;

Stable resistance to aggressive chemicals and liquids;

High flexibility with memory effect;

Refractory (water based);

High efficiency - a team of three can cover up to 1,000 square meters in an 8-hour shift.

How to apply Profix KR two-component emulsion

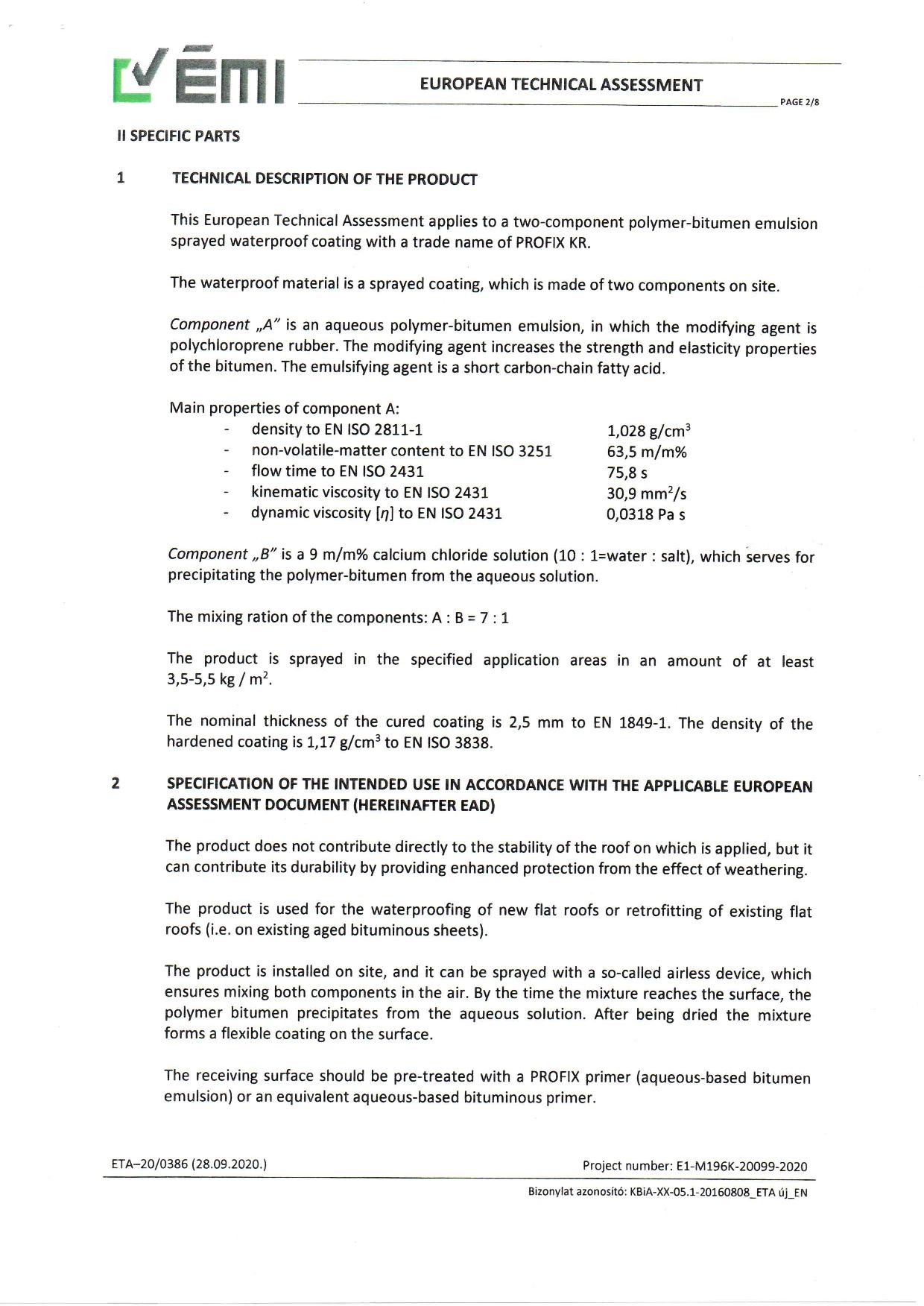

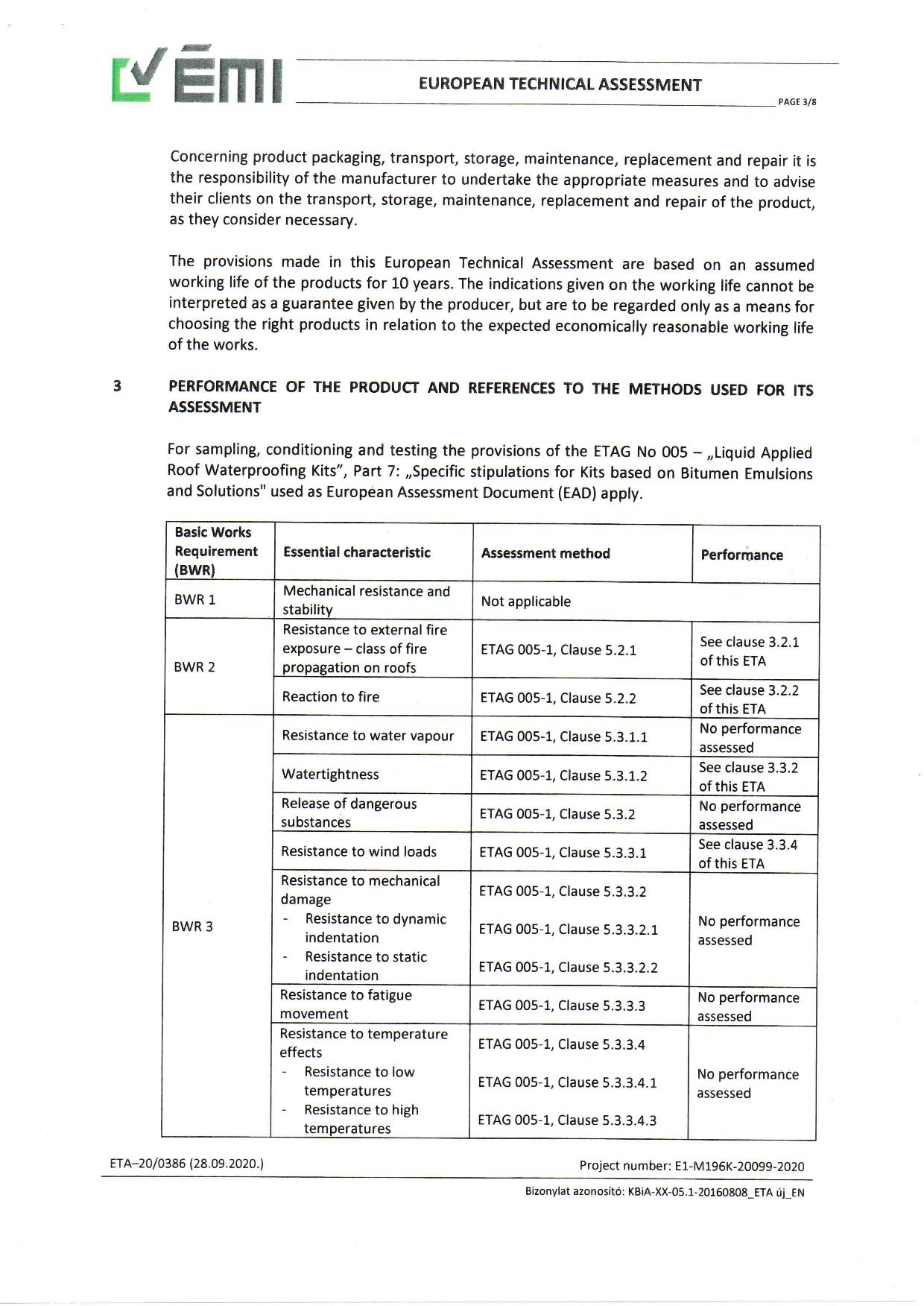

Profix KR two-component bitumen-latex emulsion is applied using a special airtight spray device by connecting two high-pressure hoses to a two-channel spray gun. At the outflow ends, there are two nozzles with a conical atomizer, through which the ingredients are sprayed: the bitumen-latex emulsion and the coagulant, which, when mixed in air, even before surface condensation, together form a gel mixture.

The material requirement of the emulsion insulation material depends on the surface area of 3.5 to 5.0 kg / m2, which corresponds to a dry film thickness of 2.5 to 3 mm. The layer thickness can be determined according to the insulation requirements. Mixing ratio of the components: 7: 1 (component A: (bituminous): component B: (solution of water and calcium chloride 10: 1.6)).

Profix KR is a one-component bitumen-latex mastic application method

The application can be applied to the surface in several coats with an Airless piston trowel or even with hand tools (such as a lime brush or roller), observing the drying time between coats. Consumption depends on the surface area of 2.5-3 kg / m2, which corresponds to a dry film thickness of 2 - 2.5 mm.

our material in use

I want to present a new insulation material that is emerging in Europe and the United Kingdom.

This insulation material can be used correctly in almost all work areas with the same insulation efficiency. The most significant advantage is that it is water-based and can be used in all high-income regions. Latex is one of the best waterproofing materials which has a very high adhesion time and has its own memory after application, which means that once it has dried on the surface, it takes on its shape.

I want to tell you about this insulating material that the manufacturer has a 20-year warranty on the water content of the area covered by this material. (provided that the contractor has followed all cleaning and application recommendations in the instructions for use described above)

in our experience, the 1000 m2 of insulation area per day can be easily covered on commercial surfaces.

There is no justification for the area of use because it is also strongly recommended for the insulation of fishponds, small home pools and the storage of large factory water and other species.

On top of these quick repairs or complete re-insulation of old roofs is a swift and affordable solution that forgets water leakage problems for a very long time.

This was just a very brief description of these rooms, but if you are interested in other areas of use, please contact us with confidence in all our services.

Send feedback

History

Saved

Community